Industrial X-ray inspection has become vital to modern manufacturing and quality assurance. It allows manufacturers to discover defects early and maintain product integrity and safety. Wellman X-Ray has been a pioneer in this field among the leaders. Wellman X-Ray is known for its innovative, reliable and efficient solutions to the needs of our industries worldwide. With their commitment to excellence and precision, it comes as no surprise that they are a trusted choice for industrial inspection solutions. This article examines why Wellman X-Ray is a frontrunner among customers in terms of offering the latest, customer-focused technology X-ray solution.

X-ray Inspection in Industry — Why It Matters

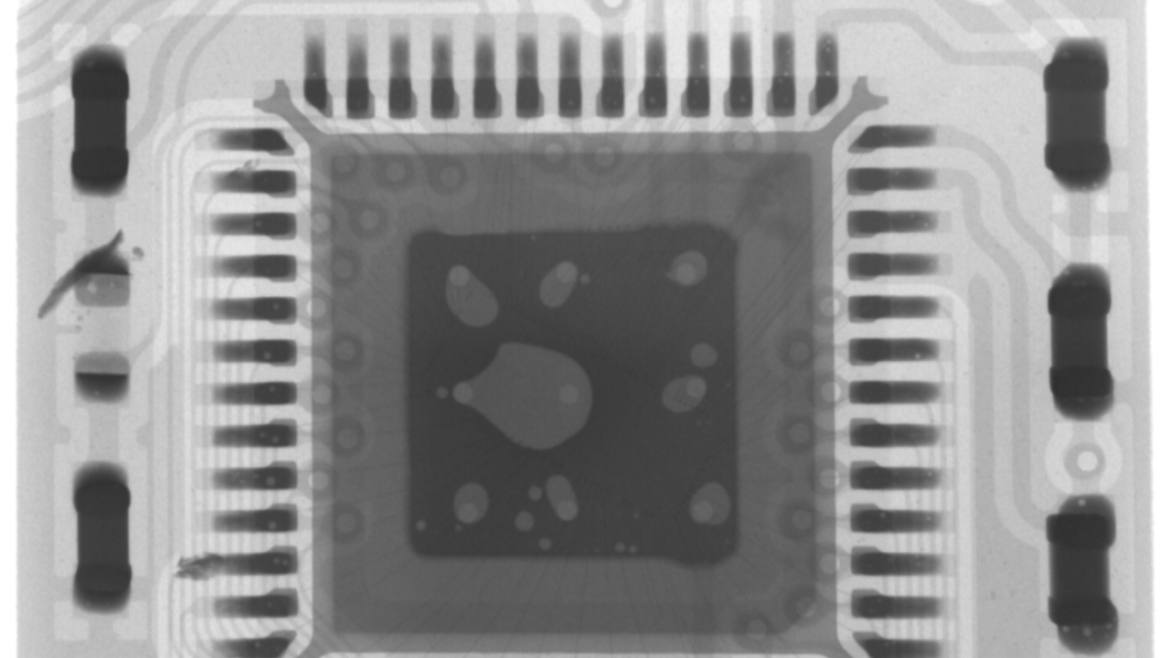

Nondestructive and non-invasive X-ray inspection is now emerging as an essential technique in ensuring quality in industries and has transformed the way industries work. It enables products to be safe and reliable by identifying internal defects such as cracks, voids and foreign materials. Early defect detection saves money via recalls and helps protect brand reputation. X-ray inspection is multi-faceted and used for industries like electronics, automotive, and aerospace. This technology protects performance and safety by detecting voids in semiconductors or ensuring structural integrity in aerospace components.

Wellman X-Ray Solutions has pioneered cutting-edge technology.

With advanced technological features, Wellman X-Ray stays ahead. Adjustable axis systems make inspections more flexible; automatic navigation software makes defect identification more streamlined. It integrates multifunctional measurement tools into its systems that allow for comprehensive analysis of defects, from BGA void detection to radius and area determination. Advancements bring about better accuracy and better optimize the inspection for different applications.

Automation is also an important focus. The inline X-ray systems from Wellman are well-suited for continuous inspection in high-volume production runs. Wellman combines precision and speed to provide unmatched efficiency for industries that require large-scale inspection. This commitment to innovation guarantees that Wellman’s solutions continue to be leaders in industrial X-ray technology.

Multiple Lines of High-Performance Products

Wellman X-Ray delivers a diverse lineup of high-performance products tailored to meet varying industrial needs:

- X-ray inspection System: It comprises an X-ray tube with microfocus and an HD flat panel detector, which contributes to high-resolution imaging and a user-intuitive interface. The use of its multifunctional measuring tools and automatic navigation software improves precision and usability.

- Inline X-Ray Inspection: This system is designed for automated production lines and allows for seamless, continuous inspection. Its precision and flexibility come from its adjustable six-axis linkage system and motion synchronization.

- X-Ray Counter System: This is a non-destructive solution for counting electronic components, such as SMDs. This system boasts ultrafast counting capabilities and AI algorithms and seamlessly integrates with the MES, ERP and WMS platforms for efficient inventory management.

- SMD Tower: It improves space utilization and component organization. Batch scanning, automatic storage, and management system connection to create traceability and accurate inventory are supported.

- X-Ray Tube and Detector: These components have a sharp, high-resolution focal spot size as small as 5 μm. Their reliability guarantees consistent performance in a wide range of industrial applications.

These products are a reflection of Wellman’s commitment to innovation, usability and efficiency.

Quality and Reliability Commitment

Quality is a top priority for Wellman X-Ray from start to finish. All their products pass through rigorous quality assurance processes to guarantee consistent performance and longevity. This also reduces downtime and costs in industries.

Simple, user-friendly software interfaces make operations easy to learn and use. Wellman’s systems are designed for optimal performance, from automated inspection procedures to advanced measurement tools. Wellman’s commitment to quality makes it a trusted partner for industries looking for a high-efficiency inspection solution.

Response and Support Systems

Minimal operational disruption requires timely technical support. Wellman X-Ray offers 24/7 Technical Support to promptly address customer needs. Remote troubleshooting and expert guidance help resolve issues quickly.

In addition, Wellman offers value-added services like training, maintenance, and equipment optimization to ensure maximum customer satisfaction. They ensure your operations run smoothly and that you use your inspection equipment to the fullest extent.

The Wellman Advantage

The synergy of advanced technology, reliability, and customer-centric solutions has contributed to Wellman X-Ray’s success. Their systems’ combination of precision and ease of use allows them to confidently help industries reach their inspection goals.

Wellman has earned the trust of the world over by offering a wide variety of innovative products and responsive customer support. Its solutions in electronics, automotive, and aerospace guarantee quality and efficiency. This leadership gives Wellman the reputation of being the go-to provider for industrial X-ray inspection needs.

Conclusion

One of the best was Wellman X-Ray because of its unwavering commitment to innovation, quality and responsiveness. They provide unmatched value to industries across the globe with cutting-edge technology, a huge product portfolio, and the best support systems.

Wellman is leading the way as manufacturing changes, making the future of industrial X-ray inspection. When you choose Wellman X-Ray, you select precision, reliability, and excellence to bring success to your operations and contentment to your customers.