Constant precision, reliability, and changeability in sourcing components to use in patient monitoring systems are essential in the competitive market of medical technology, in which Original Equipment Manufacturers (OEMs) are involved. EEG lead cables are some of these essential elements that are critical in recording the right brain activity. As an engineer with a solid reputation, Medke has been able to demonstrate its value in the OEM market by developing an excellent engineering solution, quality of material, and paying attention to patient comfort.

Accuracy in Signal Transmission

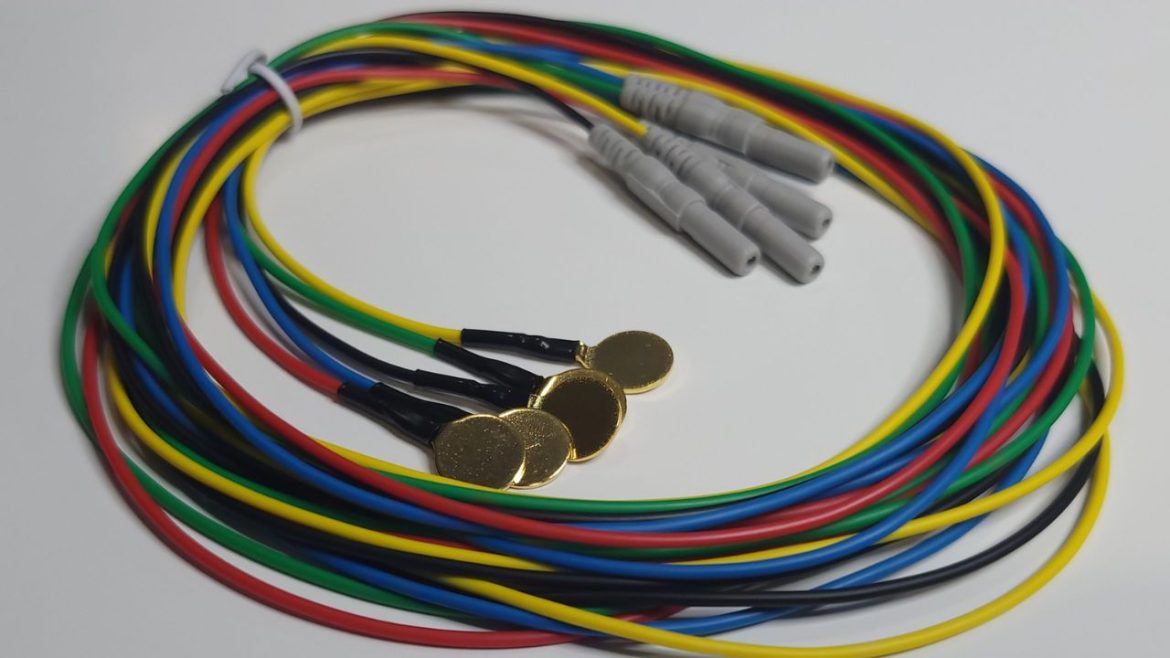

The focus on the precision of the signal is one of the most significant aspects that enable Medke EEG cables to be used in an OEM case. EEG monitoring is the recording of very small magnitude electrical signals on the scalp, and any interference or loss of signal may interfere with the accuracy of the diagnosis. The solution to this dilemma developed by Medke is to cast its cables with high-quality materials like silver, gold, and silver chloride (Ag/AgCl). These conductive materials minimize noise and maximize signal quality so that EEG systems produce reliable and clinically accurate data both in the research and in the clinical environment.

Versatile Design for Seamless Integration

OEMs need parts that are easily compatible with various systems or that can match product specifications. Medke has a very big variety of EEG cables, some of which are alligator clip cables, needles, snap cables, and casted types. Such diversity enables manufacturers to choose a cable design that better fits their device architecture, without compromising their performance. Also, Medke works closely with its OEM partners to deliver application-specific solutions by offering customized lengths, connectors, and electrode configurations.

Durability for Long-Term Reliability

Durability is a major factor in the consideration of the OEMs because medical devices are prone to being handled and sterilized several times, and also subject to constant clinical application. Medke meets such needs by choosing durable insulation material and connectors that are strengthened to resist wear and tear. Not only can this durability guarantee that the performance will be constant over the years, but it also lowers the necessity to replace items, and therefore, OEMs can provide hospitals, clinics, and research facilities with reliable products.

Concern for Patient Comfort

The role of patient comfort in medical device adoption and effectiveness is high. Painful EEG cables may compromise patient compliance, thus interfering with the quality of data gathered. Medke makes its cables of flexible, lightweight materials that fit around the head of the patient and are comfortable when the person is being monitored over a long period. Through the focus on ergonomics and technical competence, Medke may be confident that OEMs are able to provide end-users with devices that fulfill clinical requirements and improve the patient experience.

Observance of Regulatory Standards

OEM integration requires regulatory compliance, and all its EEG cables comply with international medical device standards. By implementing the strict safety, quality, and performance standards, Medke has made the certification process of OEMs easier by enabling manufacturers to launch products to the market without concerns of violating the required clinical and legal standards.

Collaborative OEM Support

In addition to the quality of the products, Medke focuses on good working relationships with the OEM partners. The company provides guidance in the process of selecting the product, its customization, and logistics, alongside the after-sales support. This is the collaborative method of developing products that enables OEMs to achieve streamlining of development, minimal lead-time, and high efficiency in production without affecting the quality of the product.

Innovation and Future Solution

Medke has maintained investment in research and development to make sure that its EEG cables can satisfy the changing needs of modern medical technology. The company offers OEMs solutions of the future by integrating the most recent advancements in terms of materials, signal processing, and ergonomic design to accommodate new monitoring devices and clinical use cases. This proactive strategy will enable OEMs to remain competitive in the market, as they will produce products that will incorporate the latest technology and will be reliable and user-friendly.

Conclusion

The EEG cables of Medke are specifically designed to be used in OEM projects due to their combination of a high level of accuracy in the transmission of the signals, flexible design, long-term reliability and durability, comfort of the patients, compliance with the working regulations, and mutual assistance. Focusing on technical and practical needs, Medke allows OEMs to create advanced patient monitoring solutions, achieve clinical standards, and improve healthcare outcomes. To manufacturers who want good EEG cable solutions that are reliable, Medke will provide a reliable partnership that is balanced in terms of innovation, quality, and performance.